Thermal Specificities

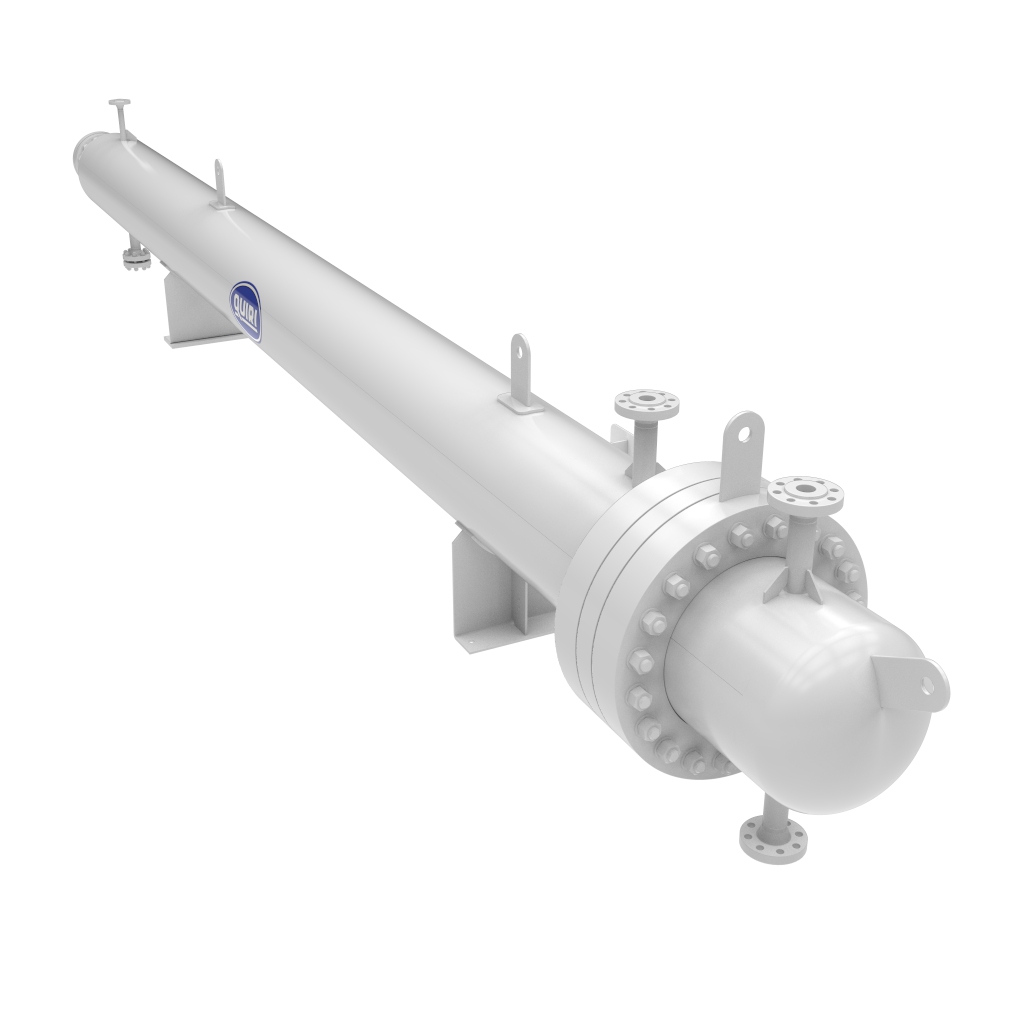

Quiri, as a specialist of heat exchangers, can provide you a water preheater.

Device delivered in France in 2020 as part of the construction of a Waste Facility

The preheater supplied by Quiri is part of a batch of 3 heat exchangers: a water preheater, a vaporizer and a steam superheater.

The Quiri thermal design heat exchanger preheats superheated water from condensates from an upstream turbine.

Some Technical Data:

| Shell Side | Tube Side | ||||

| Nature of the fluids | Superheated water / Gas 2 | Condensats / Gas 2 | |||

| Number of passes | 2 | 2 | |||

| Service Temperature (inlet / outlet) | °C | 105 | 204 | 231 | 137 |

| Service Pressure | Bar (a) | 29.5 | 28.4 | ||

| Main Dimensions | |||||

| Power | kW | 728 | |||

| Exchanged Area Installed | m² | 98.6 | |||

| Bundle tubes Type | Bended U-tubes | ||||

| Shell Diameter | mm | 450 | |||

Geometric specificities :

Horizontal tubular heat exchanger, overall length 7500 mm, empty weight 4 Tons.

Construction specificities:

Code: EN 13445

Regulation: DESP 2014/68 / EU

Calculation temperature: 0 ° C on tubeside / 300 ° C on shellside

Design pressures: 35 bar (g) on tubeside and 40 bar (g) on shellside

Test pressures: 57 bar (g) on tubeside and 65 bar (g) on shellside

Risk category IV, inspection Modula G

Welding coefficient 0.85

Metallurgy :

| Material | Norm | |

| shell | P265 GH | EN 10028-2 |

| Tubesheets | P280 GH | EN 10222-2 |

| Flanges | P280 GH | EN 10222-2 |

| Head | P265 GH | EN 10028-2 |

| Bundle tubes | P265GH-TC1 | EN 10216-2 |

| Tubes | Gr6 | ASTM A333 |

| Baffles | S235JRG2 | EN 10025 |

Tubes / Tubesheet connection: welding and expansion

Welding procedures: EN ISO 15614-1 or EN 288.3

Welders certifications: According to EN 287.1 or EN 1418

Semi-automatic MIG/MAG processes

Quality Specificities:

Quality plan according to customer specifications, European and local regulations.

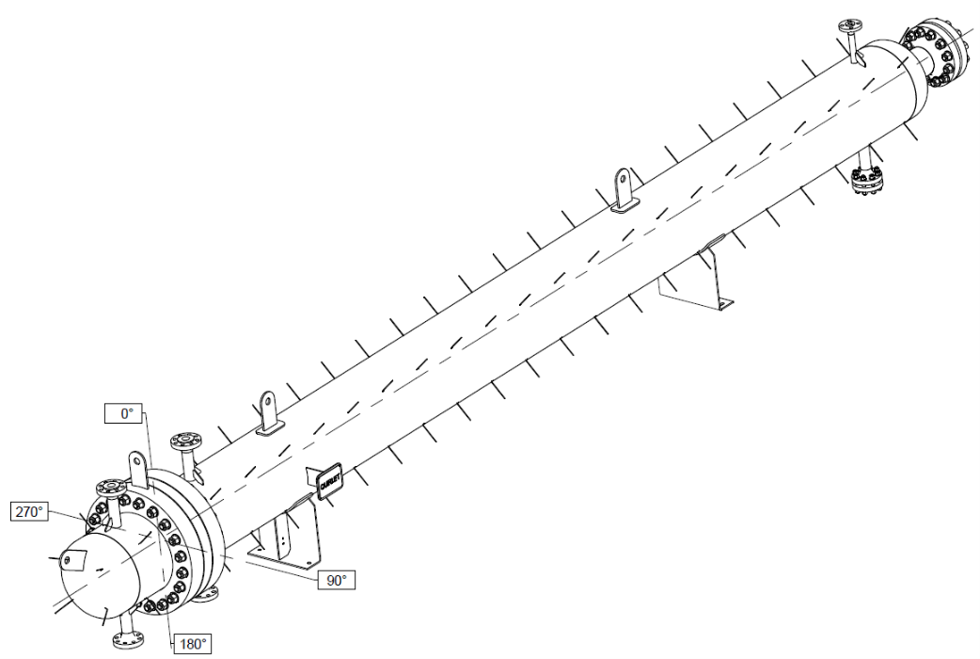

3D view: