Flanged cartridge type

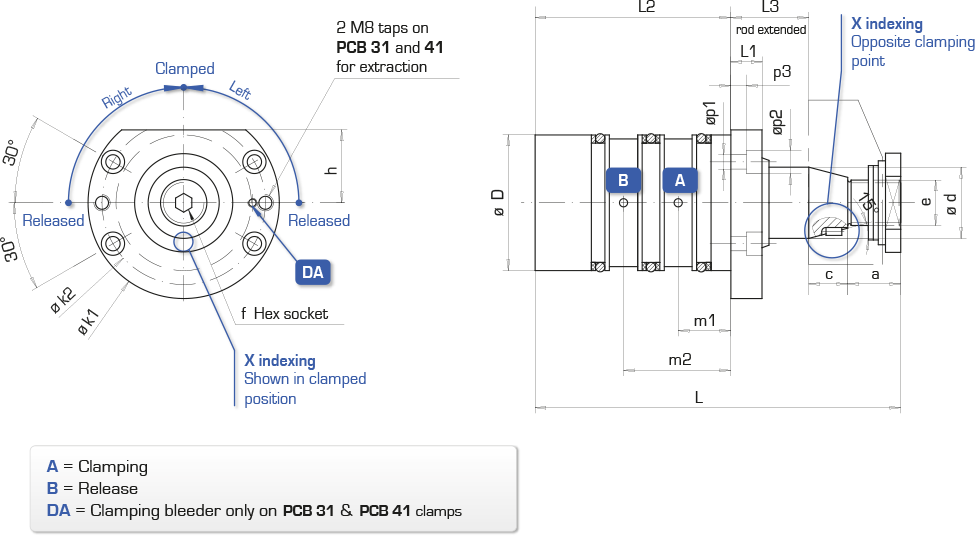

Double-acting swing clamp – Flange cartridge – 250 bar PCB

Double-acting - planar rotation

Max force at 250 bar: 4 to 24 kN

STANDARD WITH NO INDEXING

• different travel ranges on request

• choice of rotation angle in 1° increments (please specify with the order)

• metal scraper (please specify with the order)

• optional indexing (please specify with the order)

STANDARD WITH INDEXING

• different travel ranges on request

• choice of rotation angle in 1° increments (please specify with the order)

• metal scraper (please specify with the order)

• also with no optional indexing (please specify with the order)

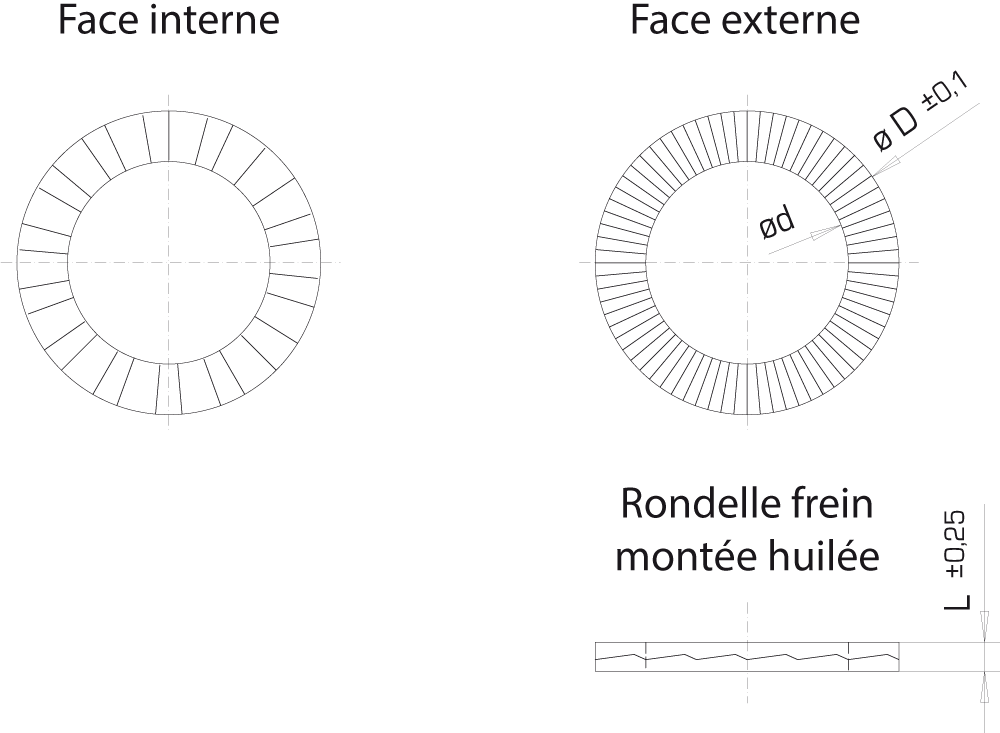

Clamps are supplied with O-rings, lock nut and lock washer.

Clamps with a 15° taper are supplied with a lock nut and lock washer (dimensions and tightening torque: see Lock washer for clamp type P11, P21 and Nut for clamp type P31 and P41).

Recess machining dimensions: see below

Definition of forces depending on clamping arm: consult the guide

Important recommendations: consult the guide

NOT INDEXED: The pin may be removed using a drift punch

| F max

at 250 bar |

Rod

ød |

Travel | Max flow rate

A |

Swept volume

A B |

Direction

of rotation |

α = 15° (with indexing) | α = 1:10 (without indexing) | |||||||||||||||||||

| Type

|

Reference

|

e1

|

Reference

|

e2

|

a

|

c

|

øD

|

f

|

h

|

øk1

øk2

|

L

|

L1

|

L2

|

L3

|

m1

|

m2

|

p1

|

p2

|

p3

|

|||||||

| kN | mm | mm | l/min | cm3 | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |||||||

| 4 | 18 | 8 | 0.4 | 5.3 | right | PCB 11 DX | 191 161/050 | M12x1.5 | 650-R-018 | M16x1.5 | 13 | 10 | 36 | 5 | 20 | 58 | 121 | 10.5 | 77.5 | 20.5 | 14 | 49 | 5.5 | 9 | 5.5 | 3D |

| 7.4 | left | PCB 11 GX | 191 161/150 | 650-L-018 | 47 | 3D | ||||||||||||||||||||

| 8 | 25 | 12 | 0.9 | 15 | right | PCB 21 DX | 191 069/050 | M16x1.5 | 650-R-025 | M22x1.5 | 16 | 14 | 52 | 6 | 28 | 76 | 152 | 12 | 95 | 27 | 16 | 56 | 6.5 | 10.5 | 6 | 3D |

| 21 | left | PCB 21 GX | 191 069/150 | 650-L-025 | 63 | 3D | ||||||||||||||||||||

| 16 | 36 | 12 | 2 | 41 | right | PCB 31 DX | 191 080/050 | M24x1.5 | 650-R-036 | M30x1.5 | 18 | 20 | 72 | 10 | 38 | 110 | 195 | 18 | 124 | 33 | 17 | 77 | 10.5 | 17 | 8 | 3D |

| 53 | left | PCB 31 GX | 191 080/150 | 650-L-036 | 90 | 3D | ||||||||||||||||||||

| 24 | 42 | 12 | 3 | 74 | right | PCB 41 DX | 191 070/050 | M30x1.5 | 650-R-042 | M36x1.5 | 20 | 22 | 85 | 12 | 45 | 125 | 218 | 18 | 143 | 33 | 22 | 88 | 10.5 | 17 | 8 | 3D |

| 88 | left | PCB 41 GX | 191 070/150 | 650-L-042 | 105 | 3D | ||||||||||||||||||||

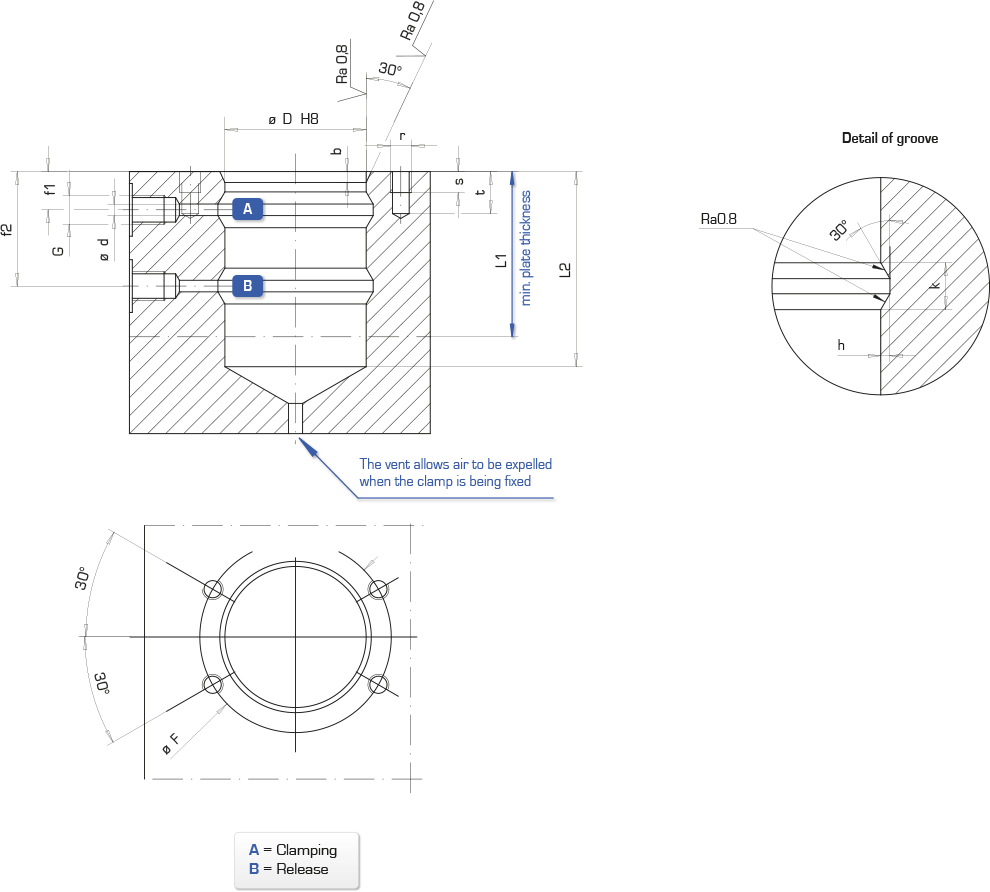

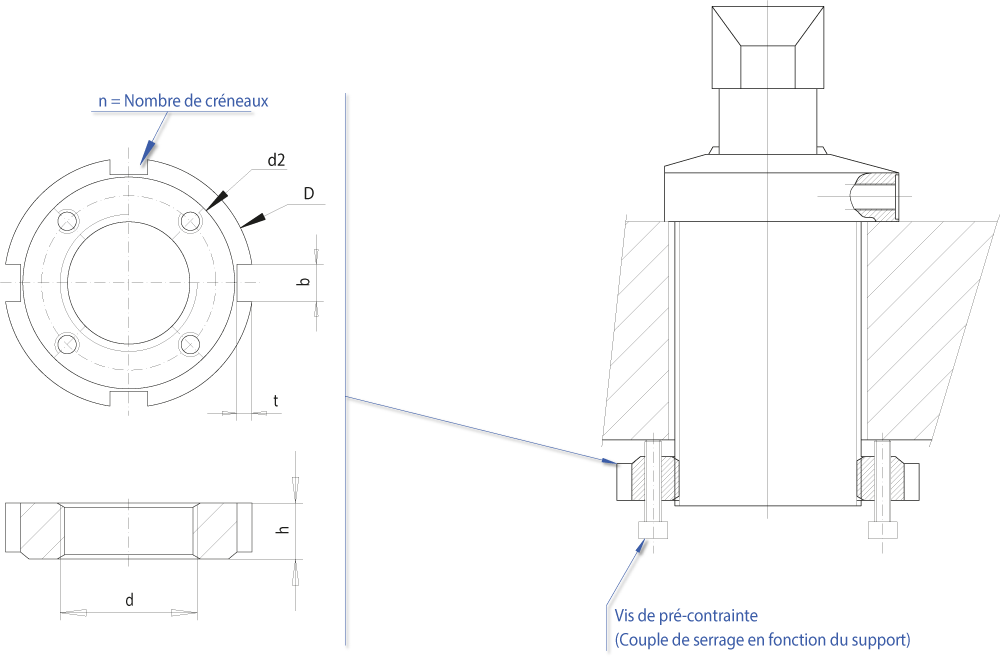

Recess machining dimensions

IMPORTANT:

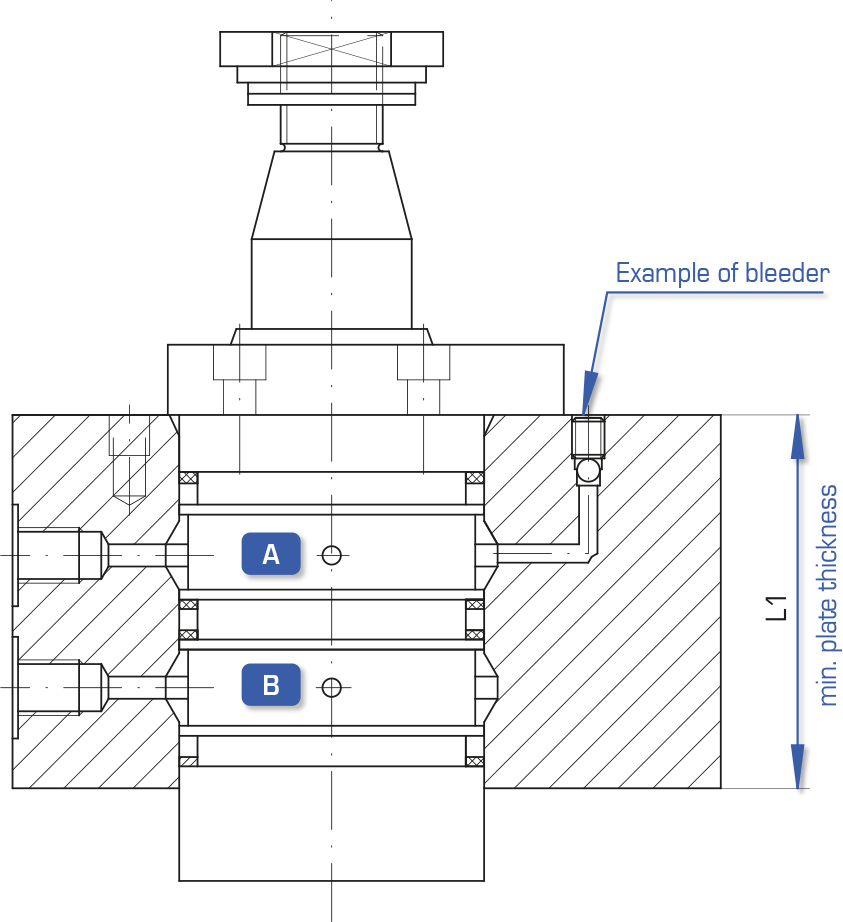

Provide bleeders at highest points of fixtures

General tolerances Js13

Round off and polish sharp angles

| Type

|

øD

H8 |

b

|

L1

min |

L2

min |

ød

|

øF

|

f1

|

f2

|

G

|

h

min |

k

|

r

|

s

|

t

|

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |||

| PCB 11 | 36 | 2 | 62 | 79 | 3 | 47 | 14 | 48.75 | G1/4’’ | 0.5 | 4 | M5 | 8 | 10 |

| PCB 21 | 52 | 3 | 70 | 97 | 4 | 63 | 16 | 56 | G1/4’’ | 1 | 6 | M6 | 10 | 12 |

| PCB 31 | 72 | 3 | 95 | 126 | 5 | 90 | 17 | 77 | G1/4’’ | 1 | 8 | M10 | 14 | 17 |

| PCB 41 | 85 | 4 | 106 | 145 | 5 | 105 | 22 | 88 | G1/4’’ | 1.25 | 10 | M10 | 14 | 17 |

For example: Fixture through a plate

Product accessories

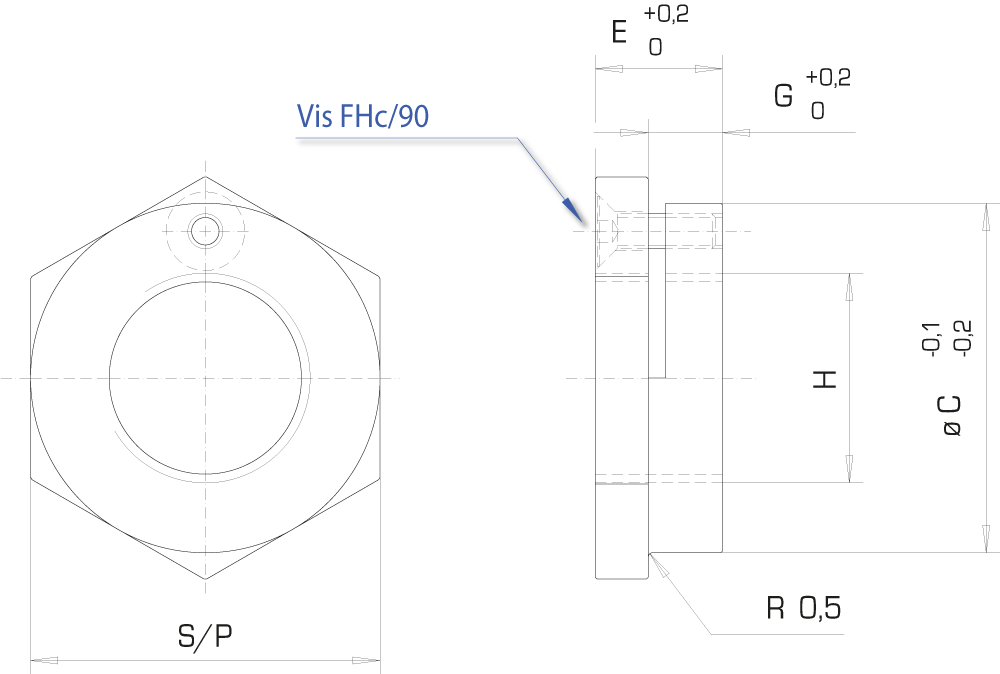

Fastening accessories: EMB

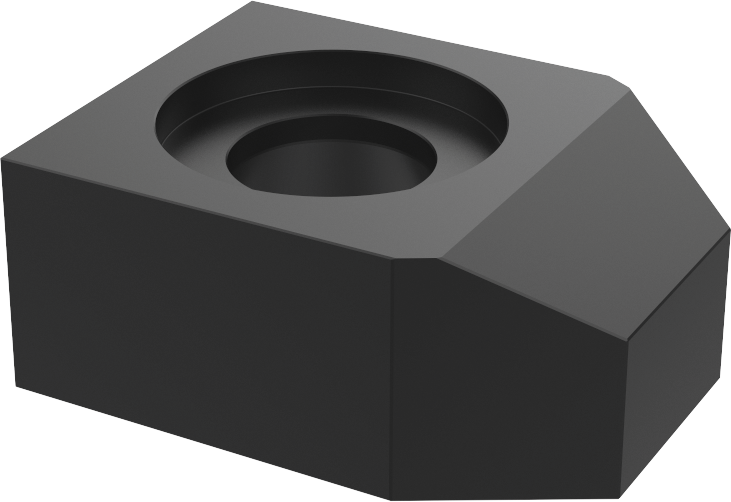

Nut for fastening threaded swing clamps

P11 - P21 - P31 - P41

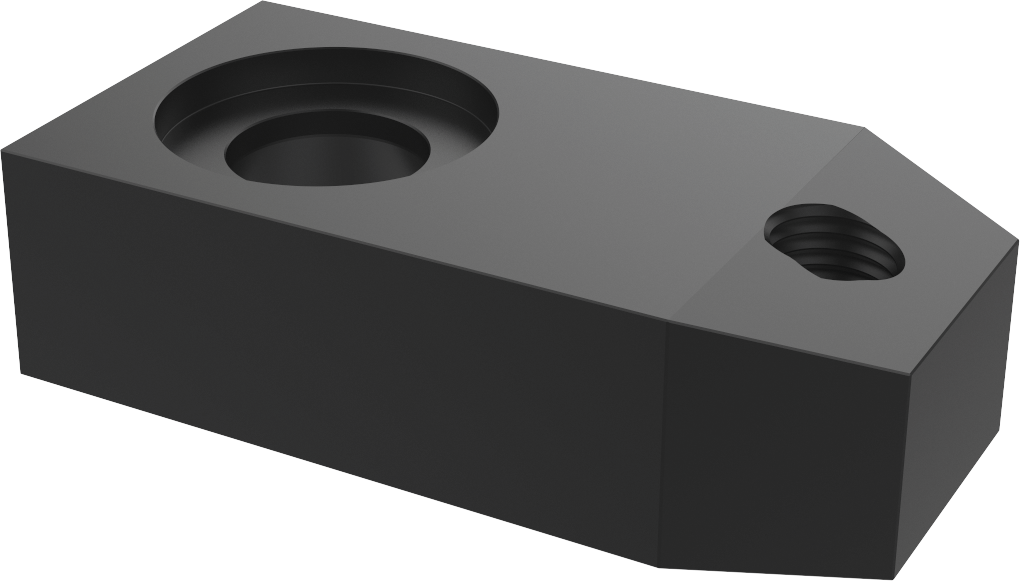

Short clamping arm – rod with 15° taper – For swing clamp size: 11 – 12 – 21 – 31 – 41 BC

for swing clamp size: 11 - 12 - 21 - 31 - 41

rod end with 15° taper

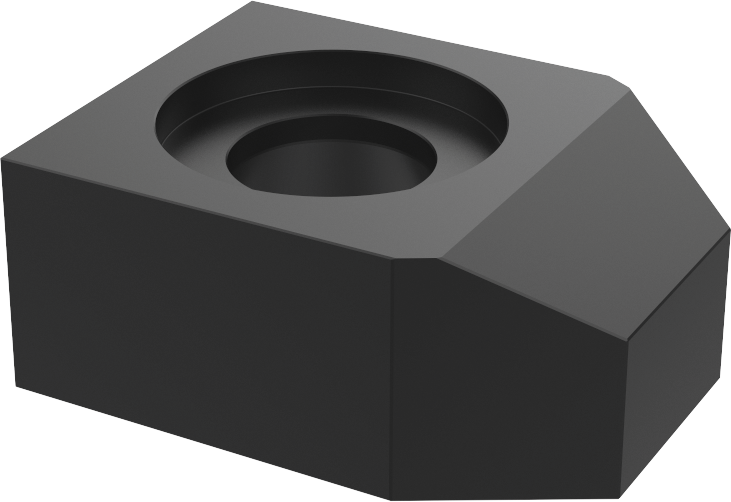

Short clamping arm – rod with 1:10 taper – For swing clamp size: 11 – 12 – 21 – 31 – 41 BCK

For swing clamp size: 11 - 12 - 21 - 31 - 41

rod end with 1:10 taper

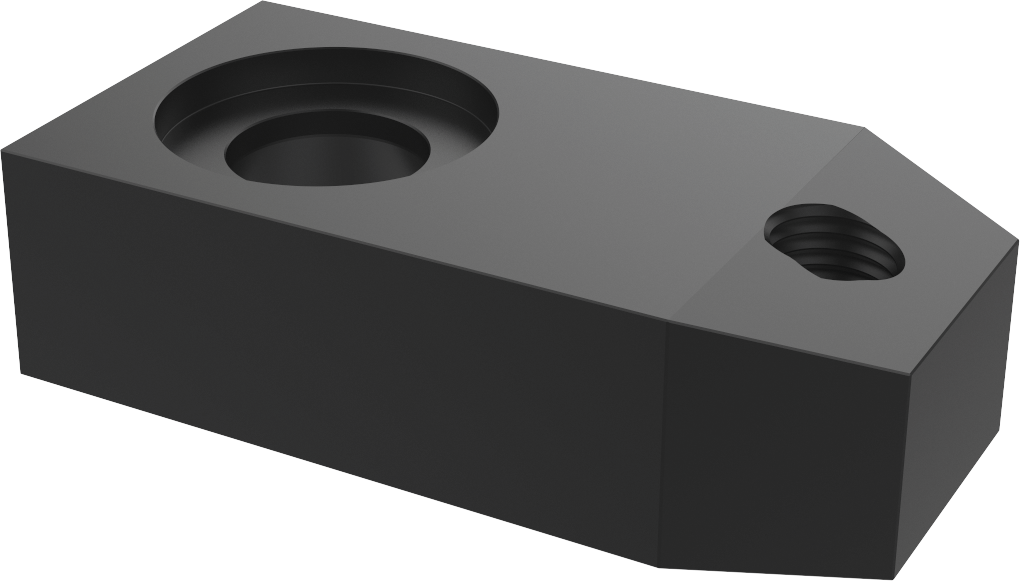

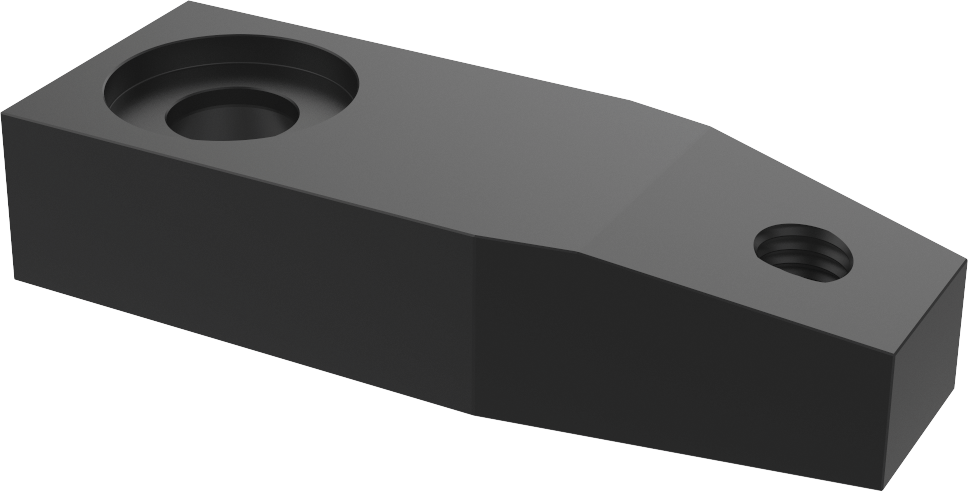

Medium clamping arm – rod with 15° taper – For swing clamp size: 11 – 12 – 21 – 31 – 41 BM

For swing clamp size: 11 - 12 - 21 - 31 - 41

rod end with 15° taper

Medium clamping arm – rod with 1:10 taper – For swing clamp size: 11 – 12 – 21 – 31 – 41 BMK

For swing clamp size: 11 - 12 - 21 - 31 - 41

rod end with 1:10 taper

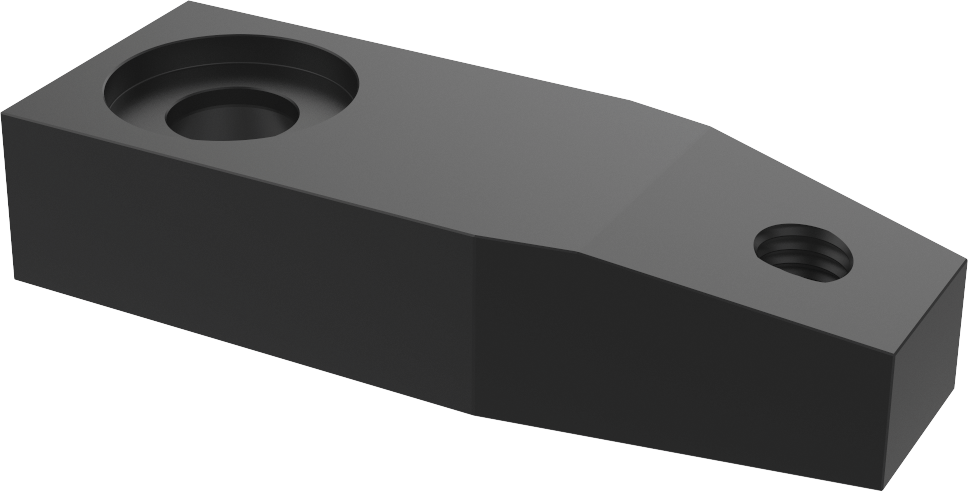

Long clamping arm – rod with 15° taper – For swing clamp size: 11 – 12 – 21 – 31 – 41 BL

For swing clamp size: 11 - 12 - 21 - 31 - 41

rod end with 15° taper

Long clamping arm – rod with 1:10 taper – For swing clamp size: 11 – 12 – 21 – 31 – 41 BLK

For swing clamp size: 11 - 12 - 21 - 31 - 41

rod end with 1:10 taper

Lock washer for clamp type P11, P21